-

Posts

96 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by Manxkiwi

-

-

Yes the piston bores are machined through from the outside and 'capped' by the silver inserts. Other monoblocks are machined from within the gap. Brembo won't disclose how they do theirs, but they clearly must use a clever sort of 90 degree machining head of some sort.

Obviously a two piece caliper can have a channel put in below the pistons. But monos would require blanking off after machining if this was done and I don't see any evidence of this.

-

Yes, my last comment related to air. I think as already said pushing the pistons right back and flushing will get the most new fluid in, short of a full disassemble job. Still keen to hear about the flow though.

Thinking about it; they are mono blocks, so I doubt there would be crossover hole at the bottom of the caliper. Now I'm going to have to take a close look at them! Ha ha.

Obviously where the banjo hole is, it would be drilled through to the bleed nipple side. But the bottom would be difficult I'd think?

-

Good thought, would be very interesting to know that. Although it may not matter as the bleed nipple would deal with the inner half and the hose would allow any air directly up the line for the outer half.

-

I think pushing the pistons back is a good idea when flushing new fluid through. You can bleed a couple of reservoirs through with pistons still back. Then, when you think the new fluid is coming through, put the calipers back on and pump back out, while topping up the reservior. That's what I do anyway, calipers will then be largely full of new fluid.

I also don't think activating the ABS unit will flush any fluid through. It doesn't circulate any fluid, it merely modulates pressure. You may however, possibly get an air bubble out though?

-

1

1

-

-

If it is brake related; have you topped up the fluid in the reservoir recently? You need a bit of an air gap in the reservoir.

-

1

1

-

-

It's probably a cost thing, but I'd like to see an o ring on bleed screws. Would be a great solution I reckon.

-

1

1

-

-

Don't forget, the suspension is compressed and tyres deformed (flattened) on the road surface in a corner. So it's difficult to look at chicken strips and say how many degrees you're over. But very small or no chicken strips is good. Impressive shots there on the Niken!!

-

Yep, clear lenses in NZ. (Also unpainted pannier lids, which is a bit disappointing!)

-

1

1

-

-

MRA, vario-tour. Extremely good IMO and isn't a barn door! Out of Europe, but great to deal with and post to NZ was pretty keen, so maybe not bad to US either?

-

1

1

-

-

I went with the Yamaha rack and top box. Well worth it I reckon. You can key the box to your ignition key too, which is nice. There isn't any sub plate or anything, box just clips in nicely.

-

I got the cheap ones from the UK, about 22 down in that Ebay link. They are a great fit, nicely made and extremely good value imo.

-

I don't know for sure about the shock length, though I would be surprised if it were different.

The new, longer swingarm variants will almost certainly require a stronger spring than the originals. More leverage.

-

1

1

-

-

If you have the GT you need to order MT10 levers. As MT09 levers foul the larger switchblock on the clutch side. That's for the Ebay ones. More expensive reputable brand ones might well clear the block?

Don't ask me how I know this!

-

2

2

-

-

On 8/26/2020 at 8:39 AM, Stew said:

My mother still talks about the time I boiled a chain in a tin of chainwax stuff in the kitchen when I was young. And when I had a bike engine in my bedroom. I may have photos somewhere

I did this too when I lived at home, many years ago. Only I spilled it in the kitchen!! F**k f**k! Luckily that day I wasn't quite as stupid as I look; the kitchen had carpet tiles. Pulled the washing machine out, swapped some tiles, hey presto!! Got away with it completely until much later when the washer sprung a leak, by then it was laughed about. I was proper worried at the time though!

-

2

2

-

-

Forget re-springing stock shock. Damping (what there is) would be way out. Really the best thing, if you can afford it and as mentioned before is a new unit from one of the decent/big brands. FYI for a big trip, two up loaded, a smidge over max load limit, I had an 850lb spring in my Nitron NTR2 (GT Tracer), which was amazing. I can't quite get enough sag for solo riding now, so I'm going down a bit, literally just sent suspension away. I'm guessing I'll end up in the high 700lbs. I am 176lb.

-

4 hours ago, Wintersdark said:

Followed Dave Moss' advice with regards to front tire and front brake caliper alignment:

So, to be honest, in 25+ years of motorcycle maintenance, I've never done this. Literally never. Put calipers in place, tighten them up. Put axle in, tighten pinch bolts. I've never done the bouncy thing to let the free leg center, nor spun the tire and held the brakes to get the calipers centered.

What he says makes so much sense, and for sure, when my calipers are even half a turn loosened I can wiggle them around quite a bit.

It's always interesting to learn The Right Way to do a simple task you've done wrong for ages, without ever even knowing what you didn't know.

Incidentally, this moved my free leg with the pinch bolt pretty substantially from where it was, it's about 2mm more out. Gotta impact fork friction, as well as alignment.

I've been doing the bounce thing for years now. But I do that before putting the calipers on (suspended to to the sides on bungees). Though if the pistons are back a bit that wouldn't be an issue. I'd be concerned to see a 2mm difference pre and post bounce. If I Push and pull my fork legs apart with the wheel out they barely flex at all. 2mm sounds an awful lot to me, if it can move 2mm sideways, it can move 2mm back and forth, I think you'd notice that?

Also clamping the calipers on may not be bad with with new pads. But if your pads are worn unevenly and you align to that, the caliper and pistons will not be square to the disc face = not good. Anyway the Tracer calipers (and many other modern radial calipered bikes) have a boss that fits into a recess in the fork carrier that has the tiniest ammount of play in it, so it's basically moot.

Just saying..

-

I think I posted these in another thread on here a wee while ago? Just two pieces of box section aluminium extrusion. I used to use bungee chords to pull them together against back tyre, but I went all pro and drilled a couple of holes to use a threaded rod to do the job, ha ha. Length shown in third pic is pretty much minimum, the GT is a bit longer than my Daytona. I have yet to get a pic of them on the bike, will post when I can get around to it. I also remember that you need the center stand up to do this, so used a paddock stand. I'm an engineer and have various paddock stands for other bikes, so for me this method is easy and cheap. I appreciate if you don't have stands and have to buy the extrusion this method would be difficult and costly perhaps. The string method is also very good if this is the case. Cheers MK.

-

Don't know if all countries are the same, but in NZ posted corner speeds are max speed for laden goods vehicles. Doubling it on a well set up road bike is quite easy 'most' of the time! There are a couple of corners I know that are a 'bit' out compared to the average.

To the OP: get a proper rear shock. Not cheap, but you'll thank me later. Cheers.

-

2

2

-

1

1

-

-

On 8/8/2020 at 5:54 PM, skipperT said:

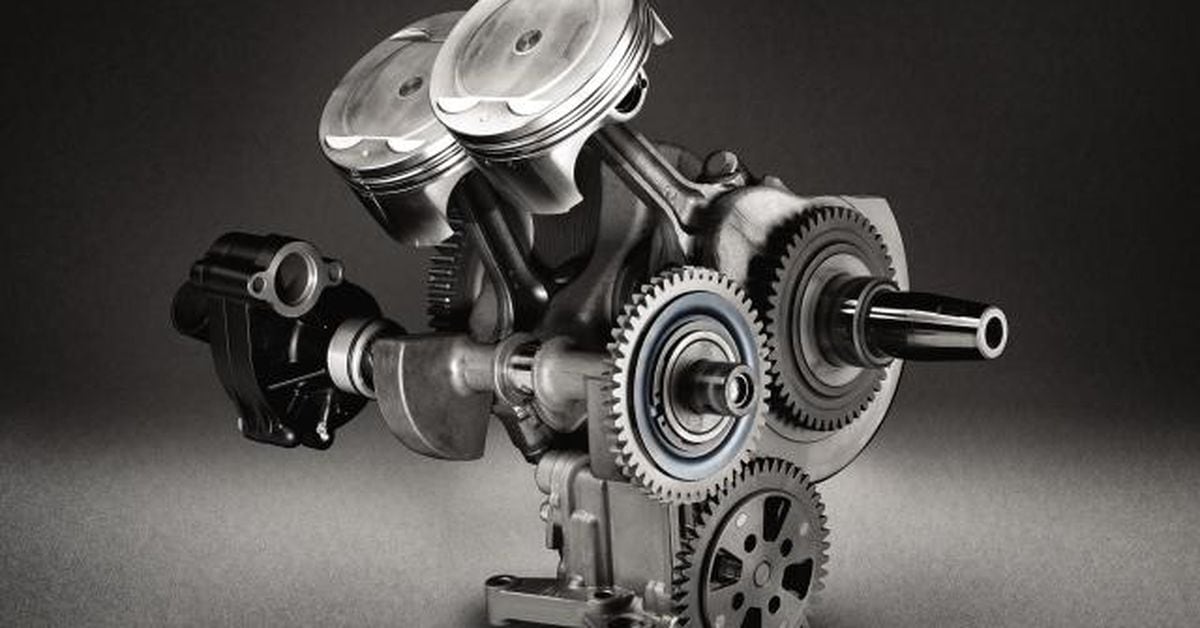

No, I was referring to our 120 degree crankpin triple motor. It is a bit of marketing lingo on Yamaha’s part, but remember that they to call it a “crossplane concept” engine design. The FZ/MT/XTZ07/XTZ12 is indeed NOT marketing nonsense as the crankpins are 90 degree.

i’ve edited my original statement since most triples do indeed use 120 degree crankpins as you pointed out.

My original intent was to correct a previous bit of mis-information within this thread about pistons being at TDC at the same time (doesn’t happen on the CP3 engine.)

Here’s some other good reading:

and:

there’s loads of info out there if one has the time...

-Skip

Yes I understood what you were saying. I was simply pointing out that the only crossplane engine is the R1. 120 degree triples and 270 degree twins are nothing new and it's a stretch to say the least for Yamaha to say 'crossplane concept'. As I was pointing out, it's simply marketing and is nothing new. I'm not wanting to ruffle any feathers, just adding my 2c. Cheers.

-

1

1

-

-

I knew you wouldn't regret it. 😉

-

1

1

-

-

On 7/2/2020 at 1:19 PM, skipperT said:

Couple comments, in the interest of sharing knowledge:

first, our engine is called a CP3 because it has a Cross Plane Crankshaft, and NO 2 pistons are at TDC at the same time. This is by design. It does however have a different vibration/sound at certain RPMs that is not like any other triple out there due to the design.

secondly, whatever engine oil you run, make sure it is motorcycle specific so that the clutch plates receive the correct lubrication during operation

-Skip

Snip is referring to 180 degree motor, think 70's Laverda. MT09 is a 'conventional' 120 degree motor. As in, the big end journals are 120 degrees to each other (not 180). CP3 is simply marketing nonsense carried over from the CP4 R1 engine, which is indeed a 'crossplane' engine; every big end journal is in a 90 position to the others when viewed down the length of the crank (hence 'cross'). I think they even call the 07 a crossplane don't they? Again marketing nonsense.

-

-

Sounds like a tough one to diagnose. I would check the wheel alignment next. With string or straight edges, don't trust the swingarm marks and don't think it's necessarily bang on from the factory. Having checked all you have already, that's all I can think of. It will be interesting to see if the problem goes away as soon as you put new tyres on?!

-

Sold my OEM Dunlops at 2500km to put new R5's on for a big trip. Sold the Dunlops and got a third of the cost of the R5's for them = win!

Front wheel noise

in FJ-09 Tracer 900 General Discussions

Posted

I just realised I didn't watch the first two videos! Doh. In the first one, it sounds to me like the floating discs clicking on their bobbins. I have Brembo track discs on my 675 and they sound like a dry clutch when you push the bike around!

Second video shows way too much drag. Have you tried taking a short ride them coming to a halt without applying the front brake, then try spinning the wheel. If it is still binding then obviously something isn't right. Even slightly binding brakes will be nudged back a tiny amount by the movement of the front end. A very small amount mind. Mind you, this thread wouldn't be here I guess if that happened.

Something I had on a rear brake of mine many years ago, was that the dust seal got partially rolled out of its groove. This was enough to stop the retract of the piston.